Silicone Self-Grip Profiles

Silicone Self-Grip Profiles

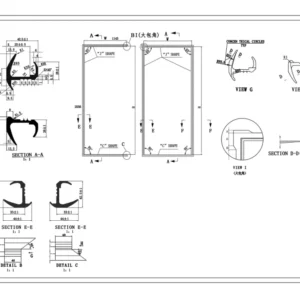

Our silicone self-grip profiles offer a reliable, flexible, and easy-to-install solution for edge protection and sealing without the need for adhesives or fasteners. With an integrated self-gripping mechanism, these profiles provide a secure fit on glass, metal, and plastic surfaces, ensuring long-lasting performance and protection.

Made from high-quality silicone rubber, they deliver outstanding resistance to UV rays, extreme temperatures, and ozone, making them ideal for both indoor and outdoor applications. These profiles are perfect for reducing vibration, blocking noise, and preventing edge wear, enhancing safety, durability, and aesthetics.

Details About Silicone Self-Grip Profiles

Details About Silicone Self-Grip Profiles

Product Description

Our silicone self-grip profiles offer a secure, flexible, and durable edge protection and sealing solution without the need for adhesives or fasteners. Designed with an integrated gripping mechanism, these profiles provide a tight fit on glass, metal, and plastic surfaces, ensuring stability and protection against impact, vibration, and wear.

Manufactured from high-quality silicone rubber, these profiles offer exceptional resistance to UV rays, ozone, and extreme temperatures, making them suitable for both indoor and outdoor applications. With easy installation and minimal maintenance, silicone self-grip profiles deliver long-term performance, protecting surfaces and improving safety and aesthetics across a variety of industries.

Applications

Silicone self-grip profiles are highly versatile and widely used across multiple industries to provide sealing, protection, and insulation in the following applications:

- Automotive and Transportation

- Seals and protects edges of doors, panels, and windows

- Reduces vibration and noise in vehicles and trailers

- Construction and Architecture

- Provides edge protection for glass panels, doors, and partitions

- Seals windows and doors to block drafts and enhance insulation

- Marine and Offshore

- Protects edges of hatches and enclosures from corrosion and wear

- Performs reliably under harsh marine conditions

- Industrial and Manufacturing

- Secures and protects machinery edges, reducing operator risk

- Acts as a seal to block dust, moisture, and contaminants in equipment

These profiles are easy to install on new or existing surfaces, providing a long-lasting solution for edge protection and sealing needs.

Common Silicone Self-Grip Profiles Materials

Selecting the right material ensures optimal performance, durability, and resistance for different applications. Below are common materials used:

- Silicone Rubber

- Advantages: Excellent temperature resistance and UV stability, suitable for outdoor and high-heat applications.

- Disadvantages: Higher cost compared to other materials.

- EPDM Rubber

- Advantages: Strong resistance to ozone, weathering, and UV exposure, ideal for outdoor environments.

- Disadvantages: Less heat-resistant than silicone.

- Neoprene Rubber

- Advantages: Good resistance to oils and chemicals, making it ideal for industrial use.

- Disadvantages: Less flexible at low temperatures compared to silicone.

Choosing silicone rubber ensures maximum flexibility, durability, and performance, especially for applications that require resistance to high temperatures and environmental exposure.

Discuss the details of

your seal solution

Submit Your Inquiry to Primesealsolution,

All the Inquiries Will Be Replied Within 12 Hours.

More Rubber Seals Support Your Project

More Rubber Seals Support Your Project

FAQ For Rubber Seals

FAQ For Rubber Seals

How to Choose the Right Material?

Customers often ask how to select the appropriate material based on their working environment (e.g., high temperature, low temperature, chemical corrosion). Common materials include EPDM, silicone, nitrile rubber (NBR), and fluororubber (FKM), each offering specific resistance properties for different applications

What Temperature Range Can the Seal Handle?

Customers often ask how to select the appropriate material based on their working environment (e.g., high temperature, low temperature, chemical corrosion). Common materials include EPDM, silicone, nitrile rubber (NBR), and fluororubber (FKM), each offering specific resistance properties for different applications

What Are the Key Points to Ensure Proper Installation?

Proper installation is crucial for performance, and customers want to know how to keep the surface clean, avoid over-stretching, and whether to use lubricants for easier installation

What Should I Do if the Seal Ages or Fails?

Over time, seals may crack or deform. Customers often inquire about how to identify these issues early and use rubber rejuvenators to prolong their lifespan or properly replace failed seals

What Should I Do if the Seal Ages or Fails?

Over time, seals may crack or deform. Customers often inquire about how to identify these issues early and use rubber rejuvenators to prolong their lifespan or properly replace failed seals

Are Rubber Seals Environmentally Friendly?

Clients in eco-focused industries may ask about the material’s recyclability and environmental compliance, especially for projects aligned with green building certifications

How Can I Extend the Seal’s Service Life?

Customers are interested in maintenance tips such as choosing suitable materials, regular cleaning, avoiding overloading, and ensuring proper use to maximize durability